Certified Quality

The company operates a Quality Management System based on ISO Standards and INMETRO standards.

Certified Quality

The company operates a Quality Management System based on ISO Standards and INMETRO standards, with the aim of satisfying the needs profitably and expectations of its customers:

Objectives of realization:

Customers: focus on customer satisfaction, being aware of their needs and expectations, and responding with the products and services they expect to receive.

Product: our product’s quality is ensured through reliable prevention and quality assurance methods applied in every phase of the pruction process.

Human Resources: promote our staff’s continuous development and training so that they may contribute towards the achievement of the company’s quality goals and asume responsability for the processes they are involved in.

Suppliers: establish a relation of mutual collaboration with our suppliers, sharing the same concept of customer satisfaction and quality.

Original Equipment Quality

Engineers and technicians specialized in production; development and marketing turn Persan Pistons into original quality products.

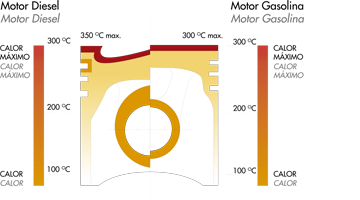

Constant temperature

Packaged pistons

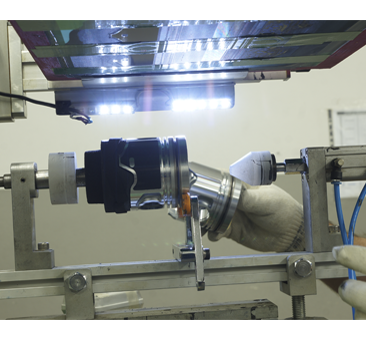

Measuring and marking

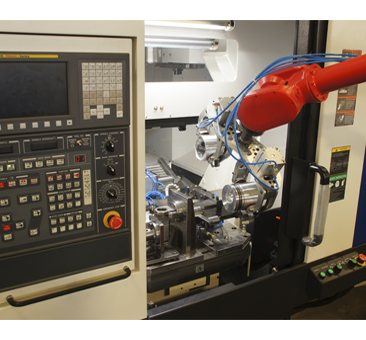

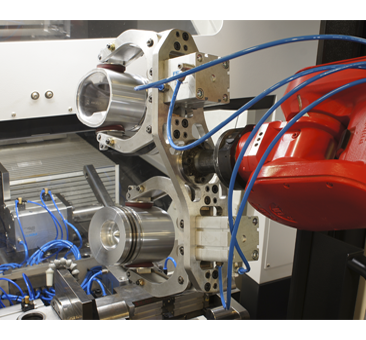

Advanced technology

We follow the latest production processes by making significant investments in technology innovation. Trough this we can achieve original quality equipment, leading us to a privileged position in the market.

Description

-

An insetion is incorporated to the smelting (ring halder-APA) and them 1st branch is mechanized to improve resistance of the 1st separator to compression (squashing). This is a very cammon technique for the diesel line.

-

Auto-thermal tins are incorporated to the smelting to control piston expansion. Thus technique is used either in gasoline or diesel engine pistons, depending on the original design.

-

A core is incorporated to the smelting on the head area which afterwards turns into a cooling channel. This technique is used in the diesel line to lower the piston temperature.

-

Superficial treatments: Tinning, this treatment contributes to the stabilization of the parts.

-

Head anodzing: this treatment contributes to lowering the temperature of the piston head and, therefore, its expansion.

-

No treatment.

-

Slot anodizing: This Treatment is applied on the 1st slot in order to improve its useful life.

-

Graphitizing: This treatment turns into a lubricant layer which helps the stabilization of the parts.